Discovering the Latest Trends in Precision aluminum casting

Wiki Article

Aluminum Casting Explained: Trick Truths and Insights for Sector Professionals

Aluminum casting works as a crucial process in contemporary production, forming parts throughout various fields. Its varied approaches, such as sand and die casting, cater to different manufacturing requirements. The unique residential properties of aluminum alloys enhance their applicability, yet tests stay in maintaining quality and effectiveness. Comprehending these facets is essential for market specialists. What are the most up to date improvements and best methods that can better optimize this procedure?Review of Aluminum Casting Processes

Crucial element of aluminum casting procedures include the prep work of mold and mildews, which may be made from sand, metal, or ceramic materials, relying on the intended use. In addition, temperature level control is essential to assure appropriate melting and solidification of aluminum.

The casting procedure permits complex designs and can achieve high levels of dimensional precision. When cooled down, the castings may go through completing procedures such as machining or surface area therapy to meet details performance requirements. Generally, aluminum casting functions as a versatile manufacturing method, efficiently meeting the diverse needs of various markets.

Sorts Of Aluminum Casting Methods

In the domain of aluminum casting, numerous methods are employed to accomplish different outcomes. Sand casting techniques supply flexibility and cost-effectiveness for complicated forms, while die casting processes supply high precision and performance for mass manufacturing. Understanding these approaches is crucial for choosing the ideal technique based on task needs.Sand Casting Strategies

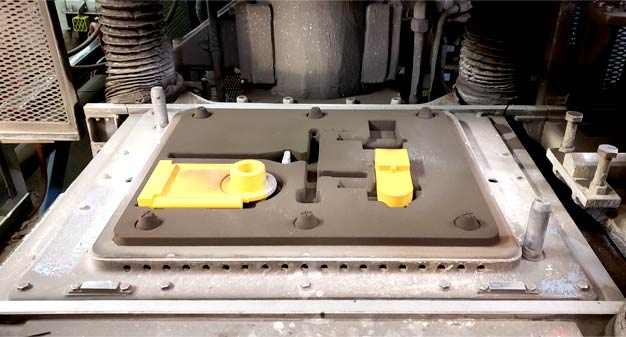

Sand casting methods stand for an essential approach in aluminum casting, where sand is utilized as a mold and mildew product to shape molten steel. This procedure involves producing a pattern from the preferred component, which is after that placed in a sand mix to create a mold. The sand is compacted around the pattern, and after removal, it produces a cavity in the shape of the component. Molten aluminum is put into this tooth cavity, enabling it to strengthen and cool. One significant benefit of sand casting is its convenience; it can suit complex shapes and big elements. In addition, the products made use of are relatively inexpensive, making it an obtainable alternative for various manufacturing applications in the aluminum sector.Die Casting Processes

Die casting procedures are a noticeable method for shaping aluminum elements, using high-pressure methods to compel liquified steel right into specifically crafted mold and mildews. This procedure is particularly favored for its ability to create intricate shapes with limited tolerances and a smooth finish. There are 2 key kinds of die casting: hot chamber and cold chamber. Hot chamber die casting appropriates for metals with reduced melting factors, allowing for faster manufacturing prices. Alternatively, cold chamber die casting is perfect for higher melting factor metals, needing a separate melting furnace. Both techniques improve effectiveness and minimize material waste, making them vital in automobile, aerospace, and consumer items industries. Recognizing these procedures aids specialists choose the most appropriate strategy for their details applications.Product Quality of Aluminum Alloys

Strength and Sturdiness

Toughness and resilience are essential attributes of aluminum alloys that make them appropriate for numerous casting applications. These products exhibit a positive strength-to-weight proportion, enabling the development of light-weight yet durable parts. When it come to tensile strength, particular aluminum alloys can be engineered to stand up to substantial lots without flawing. This building is especially crucial in sectors such as aerospace and auto, where performance and security are extremely important. In addition, aluminum alloys often retain their mechanical buildings under varied temperature level problems, ensuring constant efficiency. The innate ductility of these alloys likewise permits efficient shaping during the casting process, making it easier to generate complex geometries. Generally, the stamina and toughness of aluminum alloys add greatly to their extensive usage in sophisticated applications.Corrosion Resistance Characteristics

While aluminum alloys are treasured for their stamina and light-weight homes, their deterioration resistance is an additional crucial feature that improves their suitability for various applications. Aluminum naturally forms a protective oxide layer when subjected to wetness, which helps to avoid additional oxidation. This inherent residential or commercial property makes aluminum alloys see page especially valuable in environments prone to deterioration, such as commercial and marine setups. Furthermore, different alloy make-ups can affect resistance levels, with particular alloys particularly crafted to enhance this particular. Therapies like anodizing can additionally improve deterioration resistance by thickening the oxide layer. Subsequently, comprehending the deterioration resistance of aluminum alloys is essential for industry specialists when selecting products for projects needing resilience and long life in challenging atmospheres.Benefits of Aluminum Casting in Manufacturing

Aluminum casting deals numerous advantages in production, making it a recommended choice for different sectors. One considerable advantage is its lightweight nature, which adds to lowered transportation costs and enhanced energy performance in end products. Additionally, aluminum's excellent thermal and electrical conductivity enhances capability in applications requiring warm dissipation or electric transmission.The product's capability to be cast right into intricate shapes enables for style versatility, lowering the demand for added machining procedures. In enhancement, aluminum casting shows superior deterioration resistance, causing longer item life-spans and reduced upkeep costs.

Usual Applications of Aluminum Castings

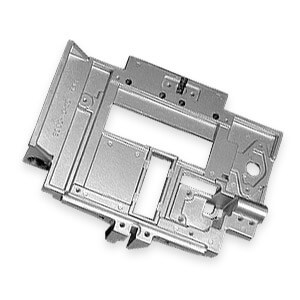

The versatility of aluminum casting enables its widespread usage across numerous industries. Usual applications include auto parts, where lightweight and corrosion-resistant elements, such as engine blocks and transmission real estates, enhance automobile efficiency. In the aerospace sector, aluminum spreadings are utilized for structural elements, supplying strength without adding considerable weight.

Additionally, the electrical market take advantage of aluminum spreadings in making units and heat sinks, where thermal conductivity is necessary. The durable goods sector also incorporates aluminum castings in products like cooking equipment, furniture, and decorative items, integrating visual appeals with capability.

Additionally, the building and construction sector uses aluminum spreadings for architectural elements, home window structures, and components, which give durability and design flexibility. Overall, the diverse applications of aluminum spreadings emphasize their relevance in modern-day manufacturing, adding to advancements in performance and product layout across several fields.

Developments and Technical Developments

As sectors proceed to develop, developments in aluminum casting modern technology are changing production processes and product capabilities. Developments in 3D printing and additive production have enabled the creation of complex geometries that were previously difficult More about the author to attain with typical approaches. These technologies enable rapid prototyping, lowering lead times and prices.Furthermore, renovations in mold style and materials have actually enhanced the casting process by boosting efficiency and lowering waste. The combination of clever production methods, such as IoT tools and real-time data analytics, permits for better surveillance and optimization of production specifications, causing higher high quality outcomes.

Growths in aluminum alloys give improved toughness, corrosion resistance, and lightweight buildings, catering to the expanding needs in aerospace and automobile markets. Jointly, these technologies are not only improving efficiency yet likewise satisfying the strenuous criteria of modern engineering applications.

Finest Practices for Top Quality Control in Aluminum Casting

Making sure high-grade outputs in aluminum casting needs adherence to finest techniques that incorporate various stages of the production process. Comprehensive material evaluation is vital to validate the top quality of aluminum alloys made use of, as pollutants can considerably impact the final item. Applying specific melting and putting methods reduces problems; keeping excellent temperature levels avoids oxidation and promotes uniformity.Mold and mildew layout plays a vital role; making use of computer-aided style (CAD) can improve accuracy and minimize human mistake. Routine surveillance of the cooling procedure is essential to prevent bending and shrinking. Additionally, using non-destructive testing techniques, such as ultrasonic or X-ray inspections, helps recognize interior imperfections without damaging the elements.

Finally, developing a feedback loop with designers and operators promotes continuous enhancement, ensuring that quality assurance steps progress alongside technical developments. By adhering to these best methods, manufacturers can enhance the dependability and performance of aluminum spreadings.

Often Asked Concerns

What Are the Ecological Influences of Aluminum Casting?

The ecological impacts of aluminum casting include significant energy usage, greenhouse gas exhausts, and potential water contamination from shop procedures. In addition, bauxite mining my company for aluminum ore can lead to habitat destruction and soil degradation.How Does Aluminum Casting Compare to Various Other Steel Casting Procedures?

Aluminum casting normally supplies advantages in lightweight components and rust resistance compared to other procedures, such as iron or steel casting, which might supply better toughness but lead to much heavier and much less corrosion-resistant items. - Aluminum Casting CompanyWhat Prevail Issues in Aluminum Castings and Their Reasons?

Common defects in aluminum castings include porosity, shrinking, and additions. Causes frequently stem from improper putting strategies, insufficient mold and mildew layout, or contamination of the molten steel, influencing the end product's honesty and efficiency.What Safety Safety Measures Should Be Taken During Aluminum Casting?

Throughout aluminum casting, important safety and security preventative measures consist of using safety equipment, making certain proper air flow, keeping a clean office, dealing with molten metal with treatment, and complying with well established procedures to minimize risks of burns, breathing threats, and mishaps.Just How Can I Enhance the Efficiency of My Aluminum Casting Procedures?

To improve performance in aluminum casting operations, one should optimize mold and mildew layout, enhance product handling, utilize automated procedures, conduct normal maintenance on devices, and invest in worker training to boost skills and efficiency.Numerous methods exist, aluminum casting incorporates several main procedures that cater to various applications and needs. Key components of aluminum casting procedures include the prep work of mold and mildews, which may be made from sand, steel, or ceramic products, depending on the intended use. Sand casting methods stand for a fundamental technique in aluminum casting, where sand is made use of as a mold material to shape liquified metal. As sectors continue to progress, developments in aluminum casting innovation are changing manufacturing processes and product abilities. Making certain premium results in aluminum casting calls for adherence to best practices that include different stages of the production process.

Report this wiki page